Thread Ring Gages - Metric

| SKU | Description | Dec. | Frac. | TPI | Pitch Diameter | Each |

|---|---|---|---|---|---|---|

| #0-80-TRG-2A GO | #0-80 UNF 2A Go Ring Gage | 0.06 | #0 | 80 | .0514" |

$224.00

|

| #0-80-TRG-2A NGO | #0-80 UNF 2A No Go Ring Gage | 0.06 | #0 | 80 | .0496" |

$224.00

|

| #0-80-TRG-2A-SET | #0-80 UNF 2A Go/NoGo Ring Gage Set | 0.06 | #0 | 80 | .0514" - .0496" |

$448.00

|

| #0-80-TRG-3A GO | #0-80 UNF 3A Go Ring Gage | 0.06 | #0 | 80 | .0519" |

$224.00

|

| #0-80-TRG-3A NGO | #0-80 UNF 3A No Go Ring Gage | 0.06 | #0 | 80 | .0506" |

$224.00

|

| #0-80-TRG-3A-SET | #0-80 UNF 3A Go/No Go Ring Gage Set | 0.06 | #0 | 80 | .0519" - .0506" |

$448.00

|

| #1-64-TRG-2A GO | #1-64 UNC 2A Go Ring Gage | 0.073 | #1 | 64 | .0623" |

$207.00

|

| #1-64-TRG-2A NGO | #1-64 UNC 2A No Go Ring Gage | 0.073 | #1 | 64 | .0603" |

$207.00

|

| #1-64-TRG-2A-SET | #1-64 UNC 2A Go/NoGo Ring Gage Set | 0.073 | #1 | 64 | .0623" - .0603" |

$413.00

|

| #1-64-TRG-3A GO | #1-64 UNC 3A Go Ring Gage | 0.073 | #1 | 64 | .0629" |

$207.00

|

| #1-64-TRG-3A NGO | #1-64 UNC 3A No Go Ring Gage | 0.073 | #1 | 64 | .0614" |

$207.00

|

| #1-64-TRG-3A-SET | #1-64 UNC 3A Go/NoGo Ring Gage Set | 0.073 | #1 | 64 | .0629" - .0614" |

$413.00

|

| #1-72-TRG-2A GO | #1-72 UNF 2A Go Ring Gage | 0.073 | #1 | 72 | .0634" |

$207.00

|

| #1-72-TRG-2A NGO | #1-72 UNF 2A No Go Ring Gage | 0.073 | #1 | 72 | .0615" |

$207.00

|

| #1-72-TRG-2A-SET | #1-72 UNF 2A Go/NoGo Ring Gage Set | 0.073 | #1 | 72 | .0634" - .0615" |

$413.00

|

| #1-72-TRG-3A GO | #1-72 UNF 3A Go Ring Gage | 0.073 | #1 | 72 | .0640" |

$207.00

|

| #1-72-TRG-3A NGO | #1-72 UNF 3A No Go Ring Gage | 0.073 | #1 | 72 | .0626" |

$207.00

|

| #1-72-TRG-3A-SET | #1-72 UNF 3A Go/NoGo Ring Gage Set | 0.073 | #1 | 72 | .0640" - .0626" |

$413.00

|

| #2-56-TRG-2A GO | #2-56 UNC 2A Go Ring Gage | 0.086 | #2 | 56 | .0738" |

$168.00

|

| #2-56-TRG-2A NGO | #2-56 UNC 2A No Go Ring Gage | 0.086 | #2 | 56 | .0717" |

$168.00

|

| #2-56-TRG-2A-SET | #2-56 UNC 2A Go/NoGo Ring Gage Set | 0.086 | #2 | 56 | .0738" - .0717" |

$336.00

|

| #2-56-TRG-3A GO | #2-56 UNC 3A Go Ring Gage | 0.086 | #2 | 56 | .0744" |

$168.00

|

| #2-56-TRG-3A NGO | #2-56 UNC 3A No Go Ring Gage | 0.086 | #2 | 56 | .0728" |

$168.00

|

| #2-56-TRG-3A-SET | #2-56 UNC 3A Go/NoGo Ring Gage Set | 0.086 | #2 | 56 | .0744" - .0728" |

$336.00

|

| #2-64-TRG-2A GO | #2-64 UNF 2A Go Ring Gage | 0.086 | #2 | 64 | .0753" |

$168.00

|

| #2-64-TRG-2A NGO | #2-64 UNF 2A No Go Ring Gage | 0.086 | #2 | 64 | .0733" |

$168.00

|

| #2-64-TRG-2A-SET | #2-64 UNF 2A Go/NoGo Ring Gage Set | 0.086 | #2 | 64 | .0753" - .0733" |

$336.00

|

| #2-64-TRG-3A GO | #2-64 UNF 3A Go Ring Gage | 0.086 | #2 | 64 | .0759" |

$168.00

|

| #2-64-TRG-3A NGO | #2-64 UNF 3A No Go Ring Gage | 0.086 | #2 | 64 | .0744" |

$168.00

|

| #2-64-TRG-3A-SET | #2-64 UNF 3A UNC Go/NoGo Ring Gage Set | 0.086 | #2 | 64 | .0759" - .0744" |

$336.00

|

Use thread setting plugs to calibrate and properly set adjustable thread ring gages. Adjustable Thread rings can only be calibrated by this method. Truncated thread setplugs have a thread with both a truncated and a full form thread for both the go and the no go member. The full form section inspects and sets the correct clearance and forms at the major diameter of the ring gage. The truncated section controls pitch diameter. A thread ring gage should be set on the full form portion of the setplug - the back portion. The ring is then turned onto the truncated portion and should have the same drag and fit as when turned through the full form. A thread ring gauge which spins quickly through the truncated section or "shakes" usually indicates wear. The ring gage should be repaired by relapping if possible or replaced. See Technical Info Document - Calibration Procedures for Thread Ring Gauges.

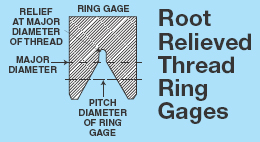

All Thread Check thread ring gauges are root relieved for longer life and more accurate gaging. The gages are manufactured with a root clearance in the major diameter which eliminates the possibility of interference from the full form section of the thread setting plug and major diameter of the part being gaged. This feature assures that the thread flanks are making proper contact.

Long Form Calibration - add $15.00 per gage member.

AGD Adjustable Thread Ring Gages and Set Plugs

Unified Thread Series (UNC-UNF-UNEF)

Standard (ANSI/ASME B1.2) 'X’ Tolerance Class 2 A or 3A

Thread Check, Inc., Thread Set Plugs are class "X" tolerance on pitch diameter and class

"W" tolerance on lead and flank angle. For class "W" tolerance - add 2 5%.

Special gages including preplates, multiple lead, ACME, Buttress, extra length, etc. are priced on request.

UNJ THREADS: ADD $35. TO GO MEMBER